Ensure Strong, Reliable Welds with Expert Weldability Analysis

Not all metals are created equal—especially when it comes to welding. Our material weldability analysis service is designed to help manufacturers, engineers, and fabricators determine whether a metal or alloy can be welded effectively and safely. From construction steel to exotic aerospace alloys, we evaluate how a material behaves during the welding process and what precautions or modifications are needed to achieve optimal results. This analysis helps prevent cracking, warping, and other costly welding defects before they happen.

How Our Weldability Analysis Works

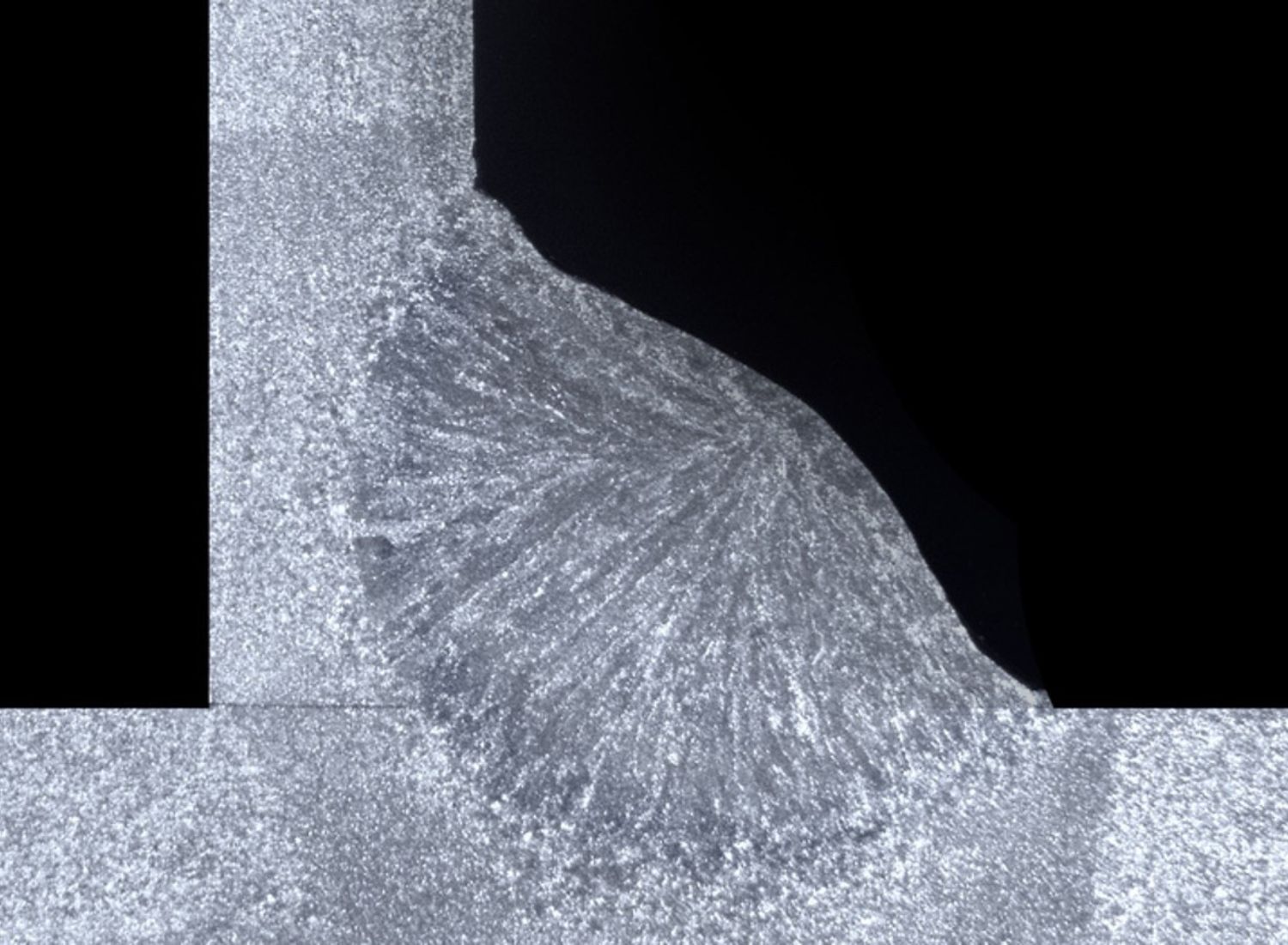

Our process starts with an in-depth assessment of the material's chemical composition, microstructure, and thermal behavior. We use a combination of metallographic analysis, mechanical testing, and simulation of welding conditions to evaluate potential challenges like hardening, hydrogen cracking, or loss of toughness. Based on the findings, we provide a detailed report outlining recommended welding procedures, filler materials, preheating or post-weld heat treatment requirements, and any risks associated with welding the material. With our expert insights, you can ensure higher weld quality, improved performance, and greater long-term reliability in your welded structures and components.