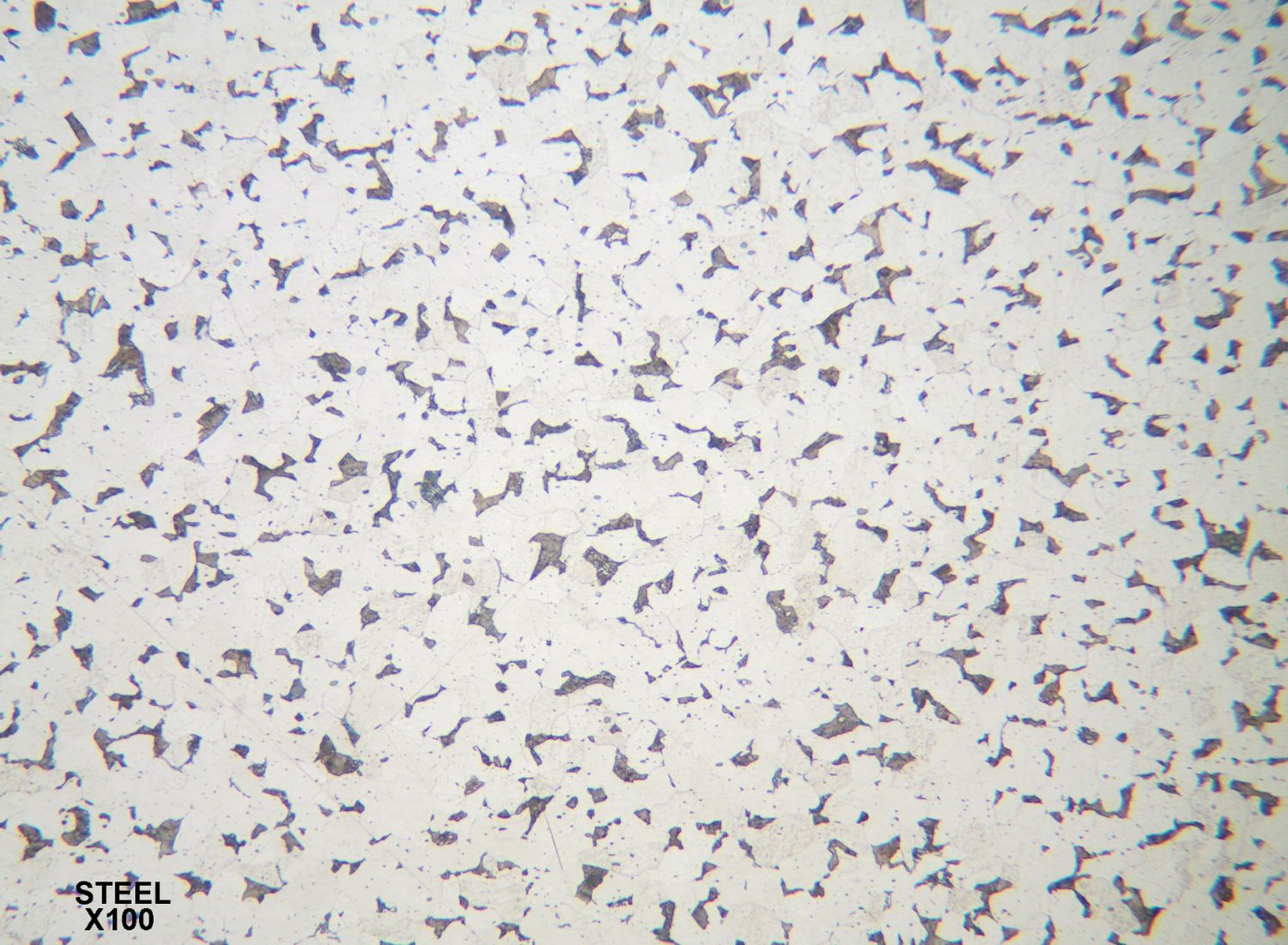

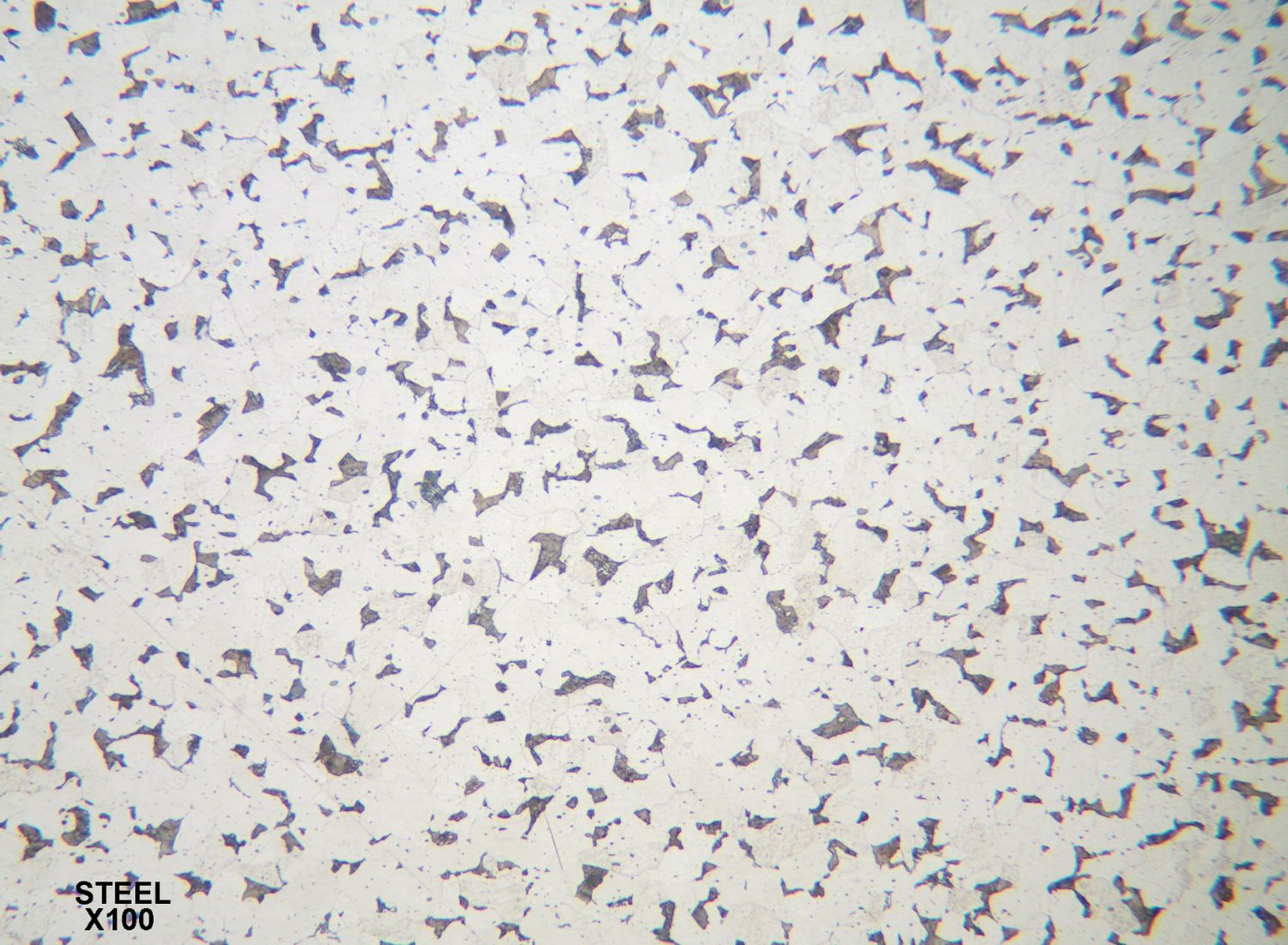

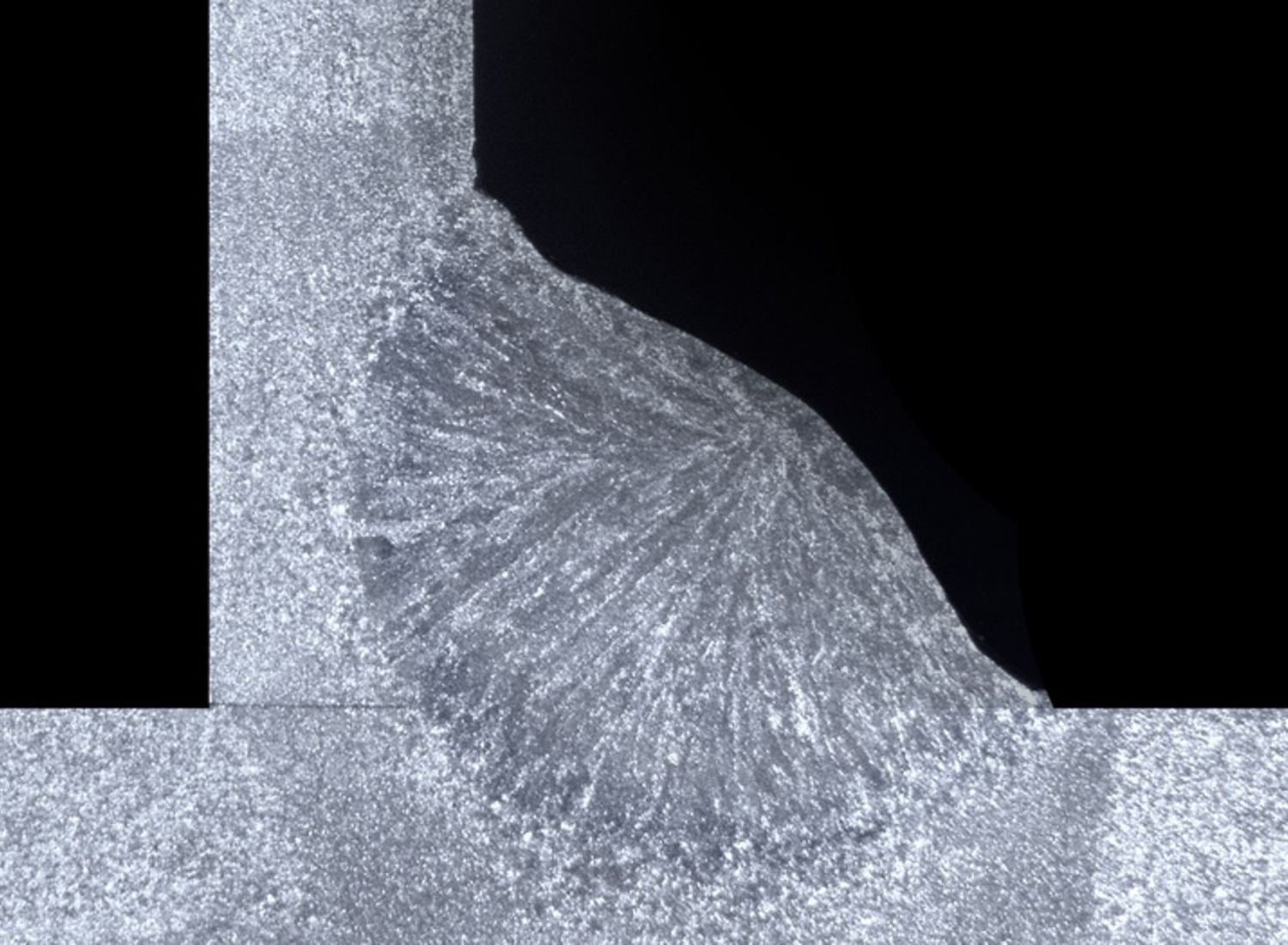

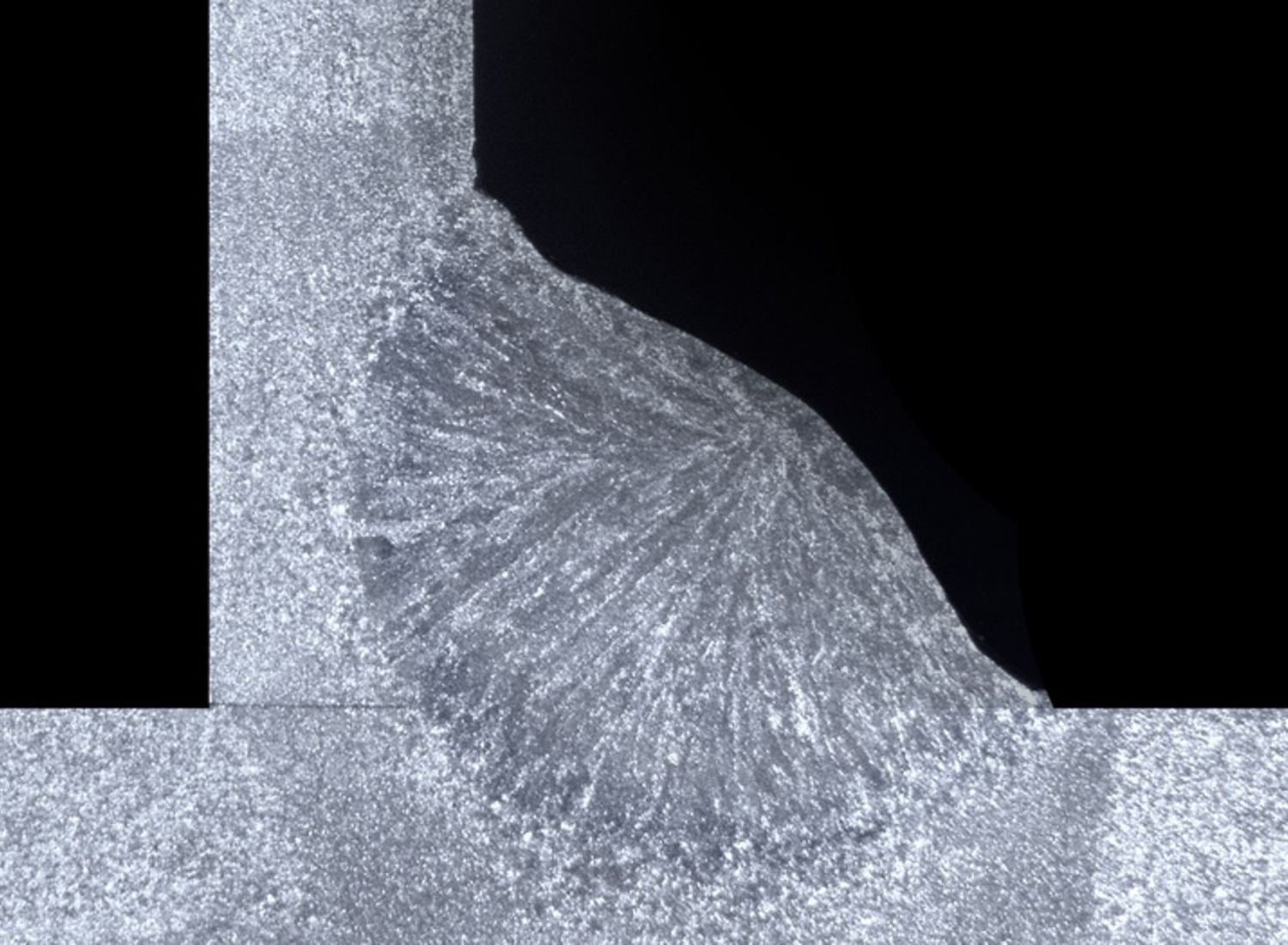

Metallurgical Investigations

We provide trusted metallurgical failure investigations to identify root causes of problems in metal and alloys, helping to reduce downtime and liability through detailed analysis, testing, and practical solutions tailored to your requirements.

Weldability of Metals

Our chemical analysis of metal by Optical Emission Spectroscopy (OES) determines the elemental composition of metals and assesses their weldability

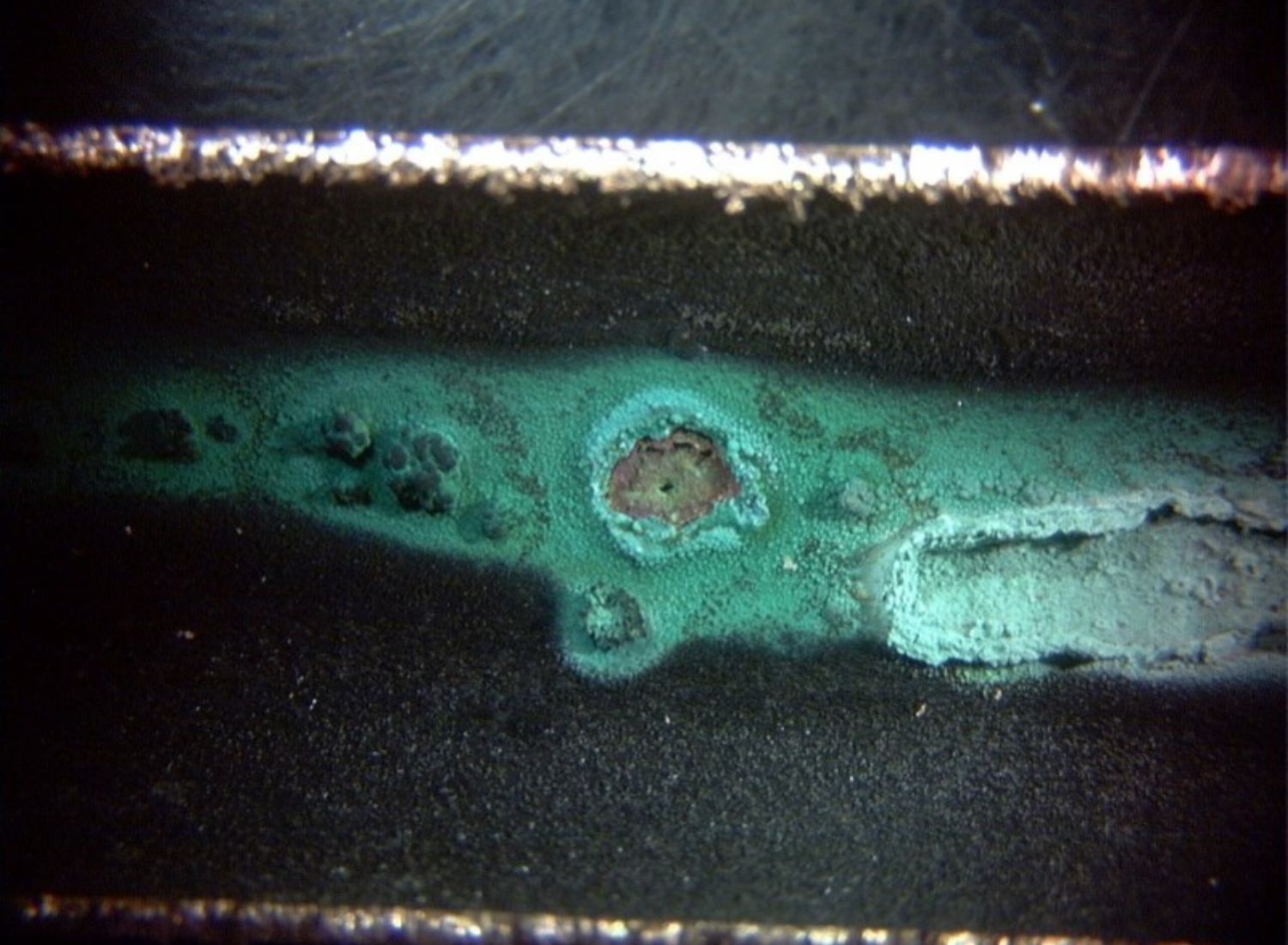

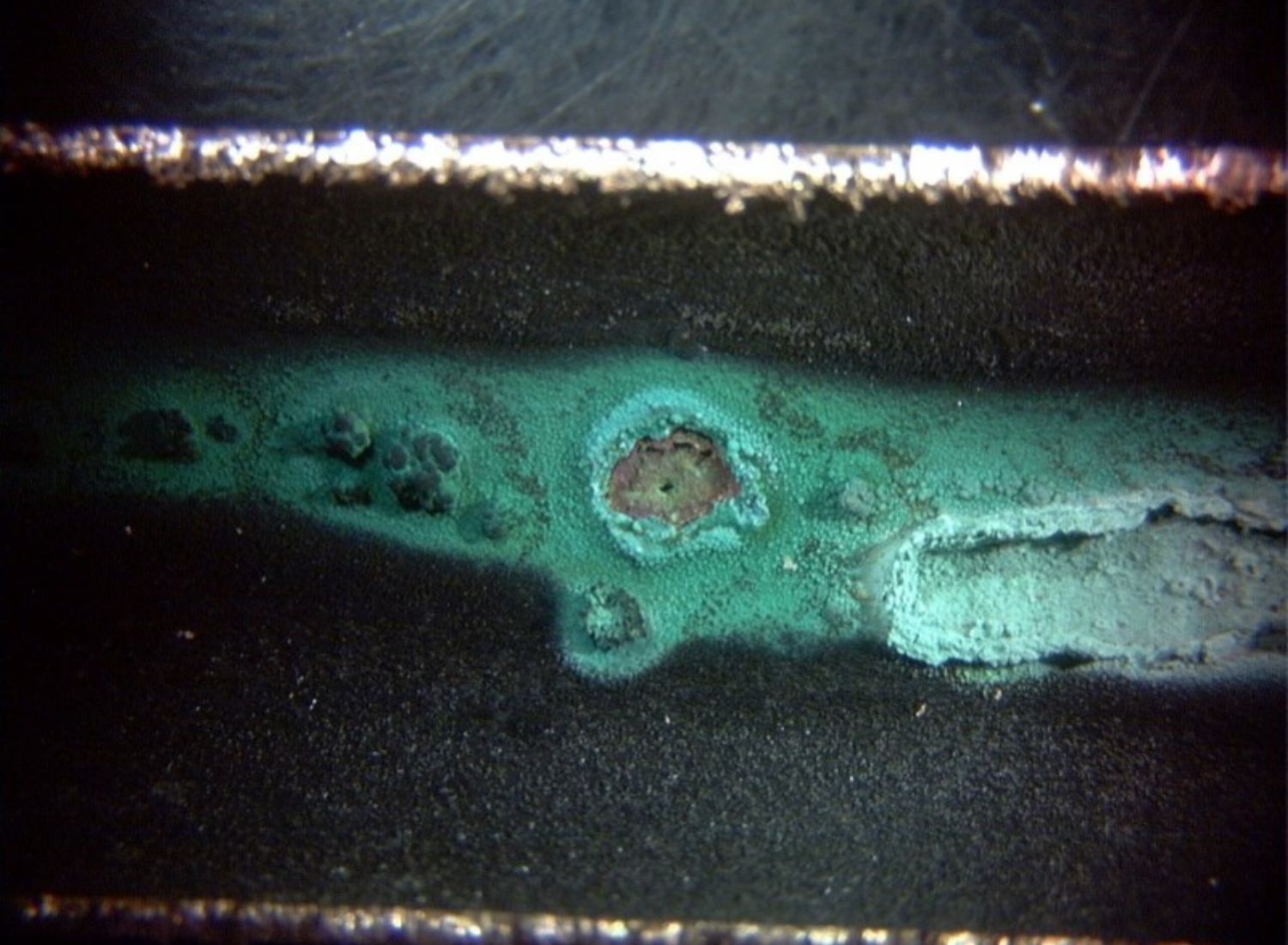

SEM and EDX Analysis

SEM and EDX provide detailed imaging and elemental analysis, revealing microstructures, contaminants, and composition for quality control, failure analysis, and research—critical for industries requiring high-precision material insights and diagnostics.

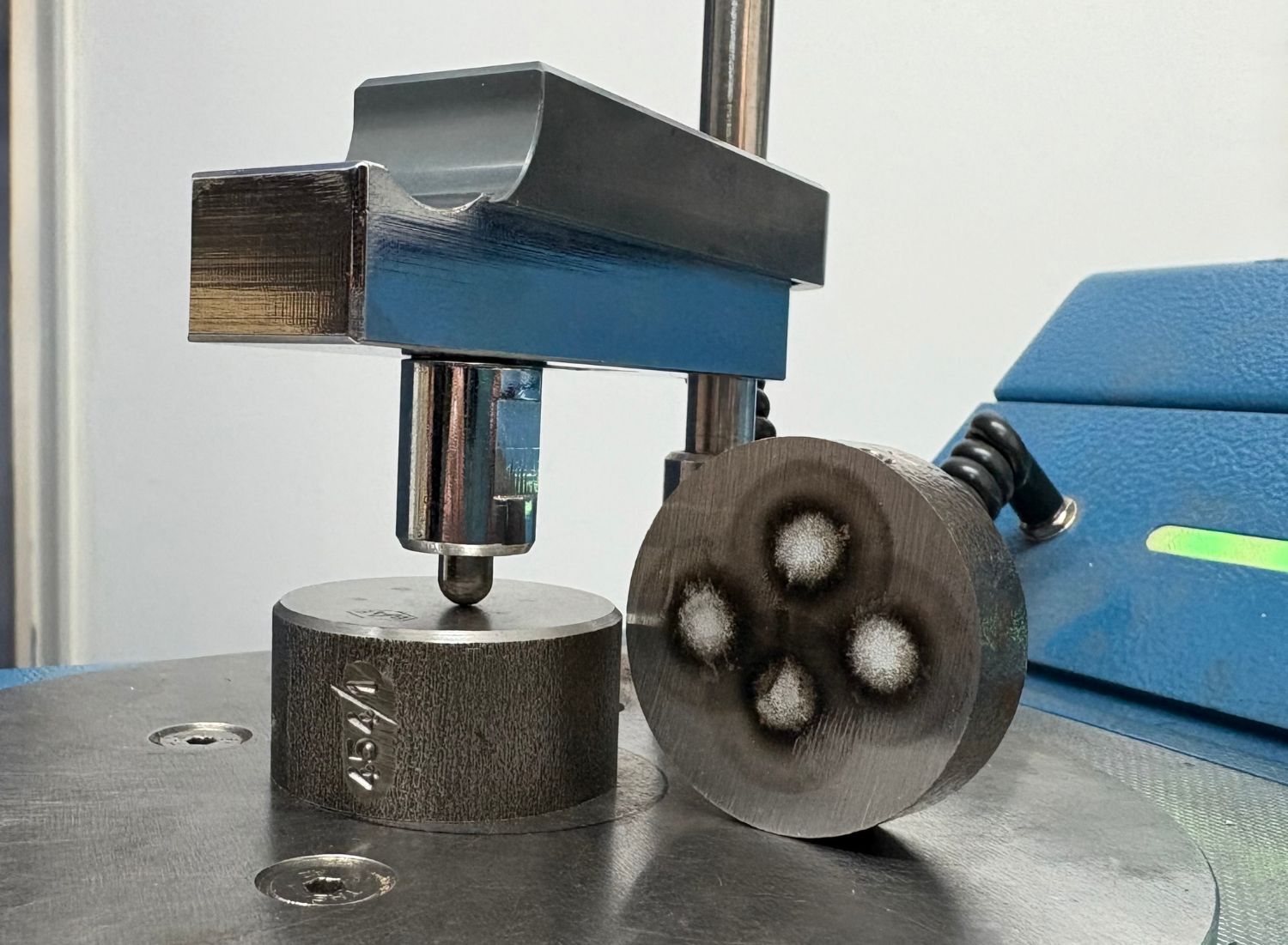

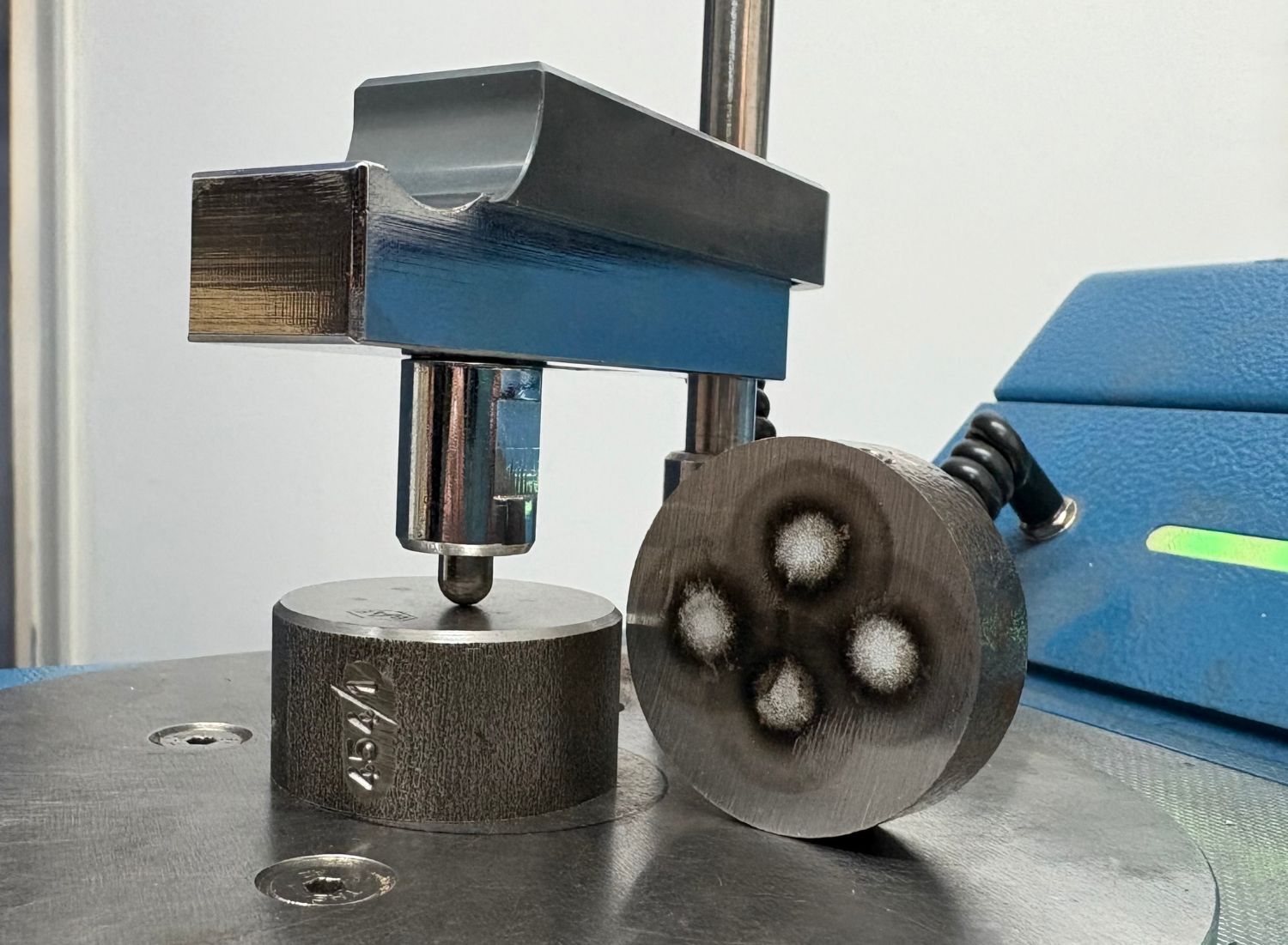

Spark OES Analysis

Spark OES delivers fast, precise metal analysis by detecting elemental composition through plasma-emitted light. Ideal for quality control and failure analysis, it ensures metals meet industry standards—even detecting trace elements reliably.